Compliance and QMS Strategy During Downsizing in Medical Device Companies

The evolution of the medical device industry is constant with frequent regulatory changes, shifts in the economy, and market demands. As a result, many organizations sometimes need to downsize to stay agile and remain financially stable. While this can be a strategic move, a structured approach will be beneficial for regulatory setbacks, compliance, and operation-related issues. In this blog, we’ll discuss how medical device company downsizing compliance impacts businesses in the medical device sector and how Elexes has helped companies maintain compliance, streamline operations, and continue growing despite workforce reductions.

If you’re leading QA or RA during restructuring, here’s what you must know to protect your company’s compliance posture, maintain uninterrupted regulatory submissions, and ensure your QMS continues to meet global standards like ISO 13485, FDA QSR, and MDSAP requirements.

Common Scenarios of Downsizing in Medical Device Companies

In the medical device industry, downsizing often occurs in response to economic challenges, shifts in regulatory pressures, mergers, acquisitions, strategic realignments, or market demand. Though it is necessary to ensure cost efficiency and operational sustainability, downsizing can create significant gaps in expertise, regulatory compliance, and process efficiency if not managed effectively.

Regulatory Risks of Downsizing in Medical Device Companies

When downsizing in medical device firms is not strategically planned, companies may experience severe disruptions, including:

● Loss of critical expertise: Subject matter expertise responsible for regulatory affairs, quality management, and compliance may be affected, leaving gaps in knowledge and essential processes.

● Risk of non-compliance: Failing to maintain compliance with US FDA, EU MDR/IVDR, Health Canada, and other international regulations can result in costly penalties, product recalls, or market restrictions.

● Operational inefficiencies: Staff and resource reduction can hamper the submissions, compliance deadlines, and might also hinder product development.

● Challenges in market expansion: Companies may lack the resources to navigate diverse global markets and ensure regulatory approval across multiple regions.

● Risk in product development: Without a dedicated team managing risk mitigation and proactive compliance, organizations may face product failures, safety concerns, and reputational damage.

For example, a mid-sized orthopedic device manufacturer received an FDA warning letter after downsizing resulted in a lack of oversight of their CAPA system, leading to unresolved nonconformances and systemic quality issues (FDA Warning Letters Database).

How Elexes Supports Medical Device Companies During Downsizing?

At Elexes, we firstly understand the challenges associated with downsizing and ensure a smooth process for:

- Regulatory compliance,

- Continuation of the operations and

- Market access.

We provide expert guidance and tailored support to fill the gaps created by workforce reductions. Our specialized services enable businesses to maintain compliance, streamline processes, and focus on core competencies while scaling efficiently.

Want a detailed list of steps to take before and after downsizing? Download our Downsizing Compliance Checklist

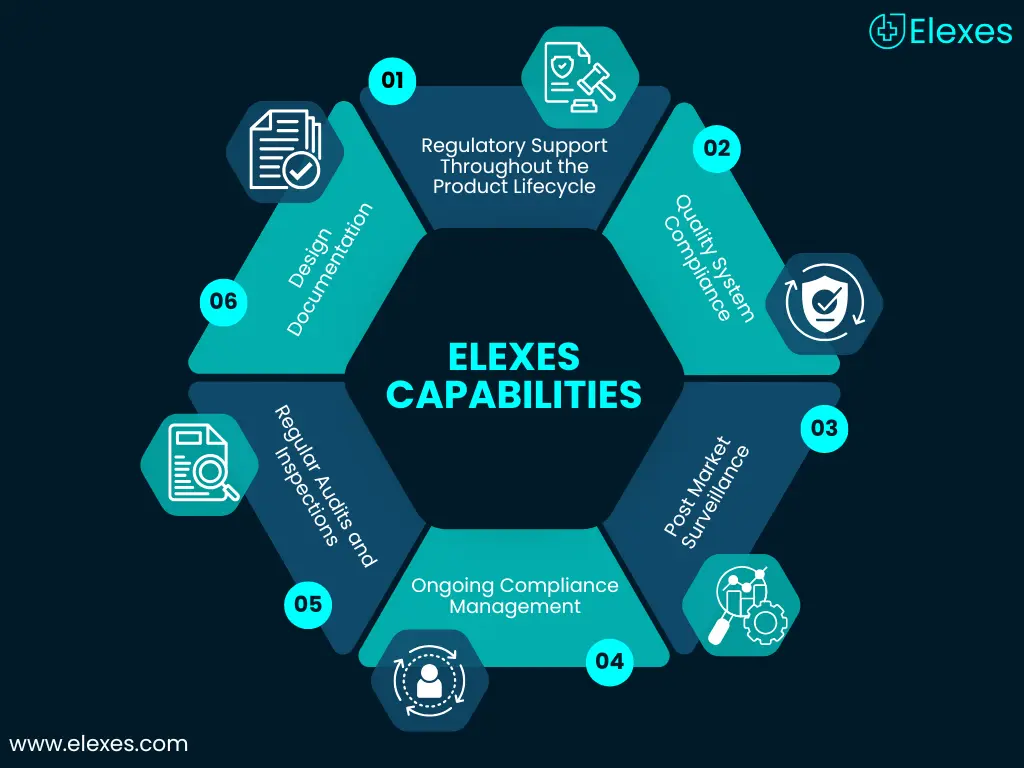

Regulatory and QMS Support by Elexes Amid Workforce Reduction

With over 10 years of experience supporting FDA, CE, Health Canada, EU MDR and ISO regulatory compliance, Elexes is a trusted partner for medical device companies undergoing organizational changes.

1. Regulatory Support Throughout the Product Lifecycle

Ensuring ongoing regulatory compliance is essential for the success and safety of medical devices and healthcare products. At Elexes, we provide expert support to help businesses navigate complex regulatory landscapes with confidence.

⦿ Regulatory Approvals: Our services include obtaining regulatory approvals, such as—but not limited to—the following:

● Health Canada Medical Device Licenses (MDLs), including license amendments,

● CE Marking support

● 510(k) submissions for new and upgraded devices to ensure seamless FDA compliance.

● Assisting during surveillance and recertification audits.

⦿ DHF Support: We focus on maintaining Design History File (DHF), and ensure that all the required design documents are up-to-date with any changes, risk evaluations, and verification efforts. Our expertise in this field makes sure that any modifications made in the device are properly evaluated.

2. Quality System Compliance

Elexes helps clients in maintaining a structured document control system, ensuring timely updates, version control, and adherence to global compliance standards. Prediction of regulatory compliance and operations can be done by maintaining a strong QMS while downsizing. We support medical device companies to enhance their quality systems to guarantee effectiveness, adherence to regulations, and ongoing development. We offer customized solutions that improve regulatory readiness, whether it’s a complete QMS redesign to expedite procedures or continuing QMS maintenance to encourage staff adherence.

Our proficiency in Non-Conformance (NC) Management and Corrective and Preventive Actions (CAPA) guarantees that quality problems are promptly recognized, resolved, and kept from happening again. In order to preserve the integrity of the product, we also supervise supplier management, confirming that vendors adhere to strict quality standards.

We support management review meetings by offering structured insights to promote ongoing improvement and aid in strategic decision-making.

3. Post Market Surveillance (PMS)

For the medical device to be safe, in line with regulatory compliance, and achieve customer satisfaction, effective PMS is essential. At Elexes, we help businesses establish a robust PMS system that ensures timely issue resolution and adherence to global regulatory requirements.. We provide comprehensive training to the company’s team to manage compliant services, ensuring customer issues are promptly addressed, minimizing risk, enhancing product performance, and supporting long-term success.

Medical devices require continuous servicing and maintenance to remain compliant with regulations. We help organizations establish servicing protocols, manage service documentation, and ensure adherence to post-market requirements.

We provide comprehensive support for the following activities as part of PMS:

⦿ Annual registration renewals

⦿ Periodic Safety Update Reports (PSURs)

⦿ Reporting of adverse events

⦿ Vigilance activities

⦿ FDA Annual Laser Reports

4. Ongoing Compliance Management

The ongoing needs are properly managed to ensure smooth operations and regulatory compliance. We at Elexes, provide support in key areas to maintain business efficiency and market readiness. We help companies optimize work by offering them Full-Time Equivalent (FTE) services to support the regulatory, quality, and compliance functions. Our FTE services ensure that the ongoing operations are maintained without causing any obstruction throughout. When the devices are ready for regulatory submissions, audits, and inspections, it is important to have proper documentation.

5. Regular Audits and Inspections

Medical device companies must stay prepared for audits and inspections to ensure regulatory adherence. Elexes provides comprehensive support in both internal and external audits to ensure compliance and readiness.

⦿ Internal Audits:

● Internal audits help organizations identify compliance gaps before regulatory/auditing authorities do. The internal audit for medical device companies is conducted in detail by taking into consideration ISO 13485, FDA QSR, MDSAP and any other relevant regulations. Our findings are accompanied by actionable recommendations to improve compliance and efficiency.

⦿ External Audits and Inspection:

● Unannounced audits by the FDA – Spontaneous inspections could be conducted by the regulatory authorities to verify the compliance. We help companies prepare for unannounced audits by conducting mock audits and readiness assessments.

● Scheduled audits – We assist in preparing for scheduled audits by the FDA, Notified Bodies, and other regulatory authorities, including certification audits, surveillance audits, and recertification audits. We also ensure document reviews, audit readiness and complete support throughout the process of audit.

6. Design Documentation

When companies downsize, maintaining compliance, especially around design documentation, can become difficult. At Elexes, we step in to support the team by managing essential records such as the Design History File (DHF), Technical Documentation, and Risk Management Files. Our expertise ensures these documents remain compliant and audit-ready, even during times of transition. This helps to maintain a smooth product lifecycle without disruption.

Conclusion

Medical device manufacturing companies can be affected significantly due to downsizing. However, with the right support, the organization can continue to grow, operate efficiently by ensuring compliance and can enter into new markets without causing any disruptions. Elexes acts as a strategic partner, providing expert regulatory guidance, quality system compliance, post-market surveillance, and audit support.

If your company has undergone downsizing and needs assistance in ensuring compliance and operational continuity, contact us today and hear it from our client to learn how Elexes can help you navigate these challenges with confidence.

💬 Need help managing QMS and compliance through downsizing?

FAQs

Do I need to notify the FDA of internal restructuring?

In many cases, no formal FDA notification is needed, but changes in responsible individuals (e.g., Management Representative) should be documented and reflected in FDA records, especially for registered manufacturers.

What happens if our Management Representative leaves?

The role must be reassigned immediately to maintain ISO 13485 and FDA QSR compliance and to duly inform the notified bodies. You must ensure ongoing management reviews, CAPA monitoring, and document control continuity.

Can we outsource regulatory functions during layoffs?

Yes, many companies successfully use external experts or Fractional VPs of Regulatory and Quality during transitions to ensure compliance and uninterrupted operations.

How do we maintain our QMS during transitions?

Establish a risk-based transition plan, ensure documented handoffs, and confirm that QMS processes like CAPA, change management, complaint handling, document control, and audits remain active and assigned to responsible parties.

What are the risks of audit failure post-downsizing?

Common risks include incomplete documentation, loss of procedural ownership, missed internal audits, and overlooked CAPAs. Proactive planning and regulatory oversight can prevent these failures.